industrial touch screen displays

industrial touch screen displays.The first is "drift", because the way of coupling capacitor is unstable, it is directly affected by temperature, humidity, finger wetness, human body weight, and dryness of the ground. Stable results, these directly violate the basic requirements of the absolute coordinate system as a touch screen, which inevitably generates drift. Some capacitive touch screens want to solve the drift problem through the 25-point calibration method or even the 96-point calibration method. It is possible that the drift is determined by the way the capacitor works. Even using dynamic calculations and empirical value lookup tables on the controller's monolithic program can only treat the symptoms but not the root causes. The multi-point calibration method was the earliest method used by large-screen projection touch panels. The purpose is to eliminate the linear distortion corresponding to the coordinates. The linear distortion of the capacitive touch screen is also very strong, mainly because the calculation of the capacitive screen is based on the four current levels and the touch point. the ideal proportion to the distance of four electrodes, due to the actual environment capacitors, capacitors and the effects of different people to use the parasitic lines, this kind of proportional relationship can not be completely linear, multi-point calibration method can only be resolved in the local distribution Linear problems cannot solve the overall drift. Another price is: the surface is fragile, and the outermost layer of extremely thin glass is very good in anti-scratch performance under normal circumstances, but it is required to be manufactured under vacuum in the process because it is afraid of hydrogen. the friability of the glass, the use of light being struck into the small holes, the capacitive touch screen which is worse: the diameter around the hole . 5 the CM area size can not be used. The actual vacuum is impossible. This extremely thin layer of glass has a 5% probability of encountering a holed product. Third is the sharpness. The capacitive screen has relatively serious reflections, and there are color distortion and blurred image characters. Capacitive touch screens have better light transmittance and clarity than four-wire resistive screens, especially some new products. With the advancement of technology, the outer surface capacitive screen can now be made on a layer of glass, as shown in Figure 2. The surface of the transparent glass plate on a layer of oxide

IQTouch K Interactive Display

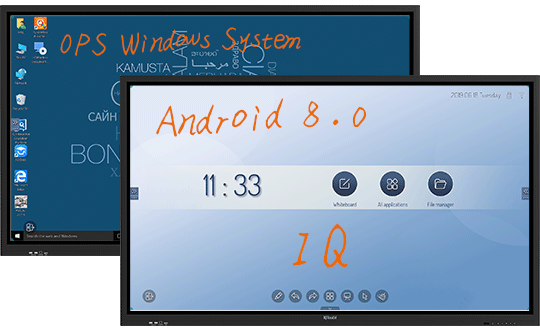

industrial touch screen displays.The first is "drift", because the way of coupling capacitor is unstable, it is directly affected by temperature, humidity, finger wetness, human body weight, and dryness of the ground. Stable results, these directly violate the basic requirements of the absolute coordinate system as a touch screen, which inevitably generates drift. Some capacitive touch screens want to solve the drift problem through the 25-point calibration method or even the 96-point calibration method. It is possible that the drift is determined by the way the capacitor works. Even using dynamic calculations and empirical value lookup tables on the controller's monolithic program can only treat the symptoms but not the root causes. The multi-point calibration method was the earliest method used by large-screen projection touch panels. The purpose is to eliminate the linear distortion corresponding to the coordinates. The linear distortion of the capacitive touch screen is also very strong, mainly because the calculation of the capacitive screen is based on the four current levels and the touch point. the ideal proportion to the distance of four electrodes, due to the actual environment capacitors, capacitors and the effects of different people to use the parasitic lines, this kind of proportional relationship can not be completely linear, multi-point calibration method can only be resolved in the local distribution Linear problems cannot solve the overall drift. Another price is: the surface is fragile, and the outermost layer of extremely thin glass is very good in anti-scratch performance under normal circumstances, but it is required to be manufactured under vacuum in the process because it is afraid of hydrogen. the friability of the glass, the use of light being struck into the small holes, the capacitive touch screen which is worse: the diameter around the hole . 5 the CM area size can not be used. The actual vacuum is impossible. This extremely thin layer of glass has a 5% probability of encountering a holed product. Third is the sharpness. The capacitive screen has relatively serious reflections, and there are color distortion and blurred image characters. Capacitive touch screens have better light transmittance and clarity than four-wire resistive screens, especially some new products. With the advancement of technology, the outer surface capacitive screen can now be made on a layer of glass, as shown in Figure 2. The surface of the transparent glass plate on a layer of oxide IQTouch K interactive touch screen feature 20-point touch and dual system -- Android 8.0 system and optional OPS Windows 10Pro system. Its 4K UHD resolution facilitates presentations and collaboration. With optional multi-screen casting software, IQClass 6.0 and installation-free IQClass Plus software, IQTouch K Series can help create an interactive and collaborative teaching atmosphere in class.

Let’s See IQTouch K Interactive Display

4K UHD Display

Stunning 4K UHD can display a cystal clear image on

screen.

20 Touch Points

Enable an interactive and collaborative teaching atmosphere

in classroom.

Built in Wifi hotspot & Optional

Multi-screen casting Software

Support to cast your devices to the screen wirelessly,

and your devices can control the screen wirelessly.

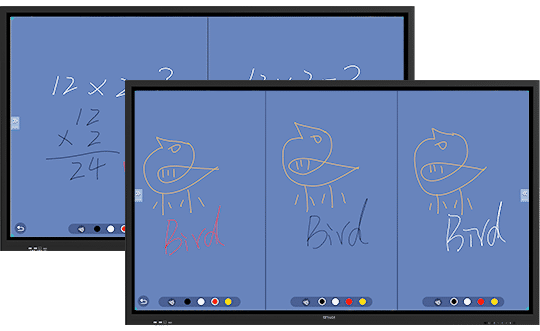

Easy-to-Use Built-in Whiteboard

Software

Built-in Whiteboard software under Android system allow to do

two separate screen teaching and three separate screen teaching.

All-channel Annotation

Enable to annotate under Android system and

Windows system.

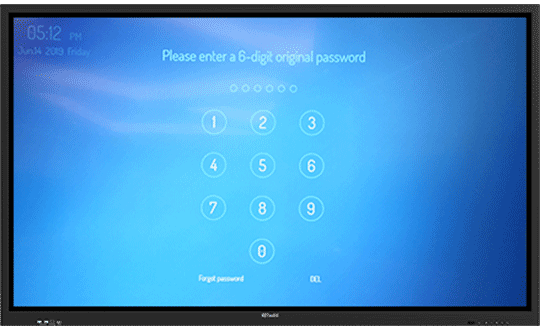

Power On/Off Lock and Screen Lock can

be Set with A Password Respectively

Support to lock screen and lock power on/off button

to avoid student

malfunction and secure privacy.

To compare with our other IQTouch Series

RESOURCE FOR YOU

Resource for you

Product Tag

Send us a message

Get in touch

-

![icon-phone]() +86-591-38202660

+86-591-38202660

-

![icon-mob]() +86-15280405902

+86-15280405902

-

![icon-mail]() iqboard@iqboard.net

iqboard@iqboard.net

-

![icon-addr]() 6th Bldg. High-Tech Base.

6th Bldg. High-Tech Base.

Fuzhou FuJian Prov. China

Solutions

Copyright © 2017.Returnstar Interactive Technology Group Co., Ltd All rights reserved.