touch screen interactive vending machine

touch screen interactive vending machine.Its structure consists of two highly transparent conductive layers, usually the lower layer is ITO glass (commonly referred to as ITOGlass), and the upper layer is ITO thin film material (commonly referred to as ITOFilm), which are separated by fine insulation points in the middle. At present, there are products on the market that use ITO glass or other transparent ITO materials on both sides. When there is no pressure on the surface of the touch screen, the upper and lower layers become insulated; once pressure is applied to the touch screen, the upper and lower circuits are conducted. At this time, the controller applies driving voltages in the X-coordinate direction and the Y-coordinate direction to detect the XY coordinates of the contacts, thereby clarifying the positions of the contacts. The upper and lower layers of the resistive touch screen are sealed by bonding. The signal is generated in the middle of the sandwich, so it can be protected from dust, water and dirt, and has good performance. At present, the manufacturing technology of resistive touch screens has also made great progress. The large-scale production process has been generally used. The batch consistency of products has obvious advantages in various touch screens. This is also the fact that resistive touch screens can meet large quantities. Important reasons for supporting products. The technical principle of the resistive touch screen will be explained in detail in the text of the next section.

IQTouch K Interactive Display

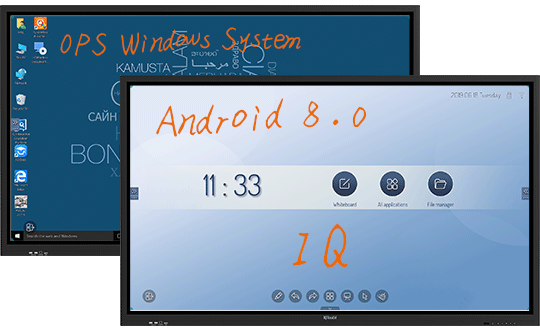

touch screen interactive vending machine.Its structure consists of two highly transparent conductive layers, usually the lower layer is ITO glass (commonly referred to as ITOGlass), and the upper layer is ITO thin film material (commonly referred to as ITOFilm), which are separated by fine insulation points in the middle. At present, there are products on the market that use ITO glass or other transparent ITO materials on both sides. When there is no pressure on the surface of the touch screen, the upper and lower layers become insulated; once pressure is applied to the touch screen, the upper and lower circuits are conducted. At this time, the controller applies driving voltages in the X-coordinate direction and the Y-coordinate direction to detect the XY coordinates of the contacts, thereby clarifying the positions of the contacts. The upper and lower layers of the resistive touch screen are sealed by bonding. The signal is generated in the middle of the sandwich, so it can be protected from dust, water and dirt, and has good performance. At present, the manufacturing technology of resistive touch screens has also made great progress. The large-scale production process has been generally used. The batch consistency of products has obvious advantages in various touch screens. This is also the fact that resistive touch screens can meet large quantities. Important reasons for supporting products. The technical principle of the resistive touch screen will be explained in detail in the text of the next section. IQTouch K interactive touch screen feature 20-point touch and dual system -- Android 8.0 system and optional OPS Windows 10Pro system. Its 4K UHD resolution facilitates presentations and collaboration. With optional multi-screen casting software, IQClass 6.0 and installation-free IQClass Plus software, IQTouch K Series can help create an interactive and collaborative teaching atmosphere in class.

Let’s See IQTouch K Interactive Display

4K UHD Display

Stunning 4K UHD can display a cystal clear image on

screen.

20 Touch Points

Enable an interactive and collaborative teaching atmosphere

in classroom.

Built in Wifi hotspot & Optional

Multi-screen casting Software

Support to cast your devices to the screen wirelessly,

and your devices can control the screen wirelessly.

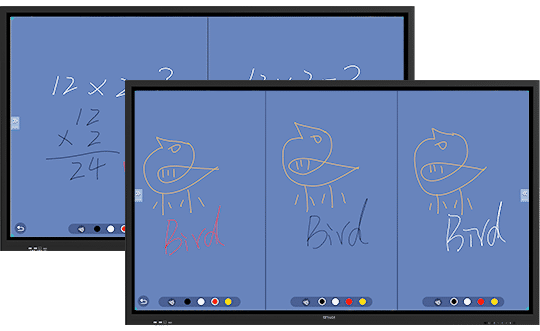

Easy-to-Use Built-in Whiteboard

Software

Built-in Whiteboard software under Android system allow to do

two separate screen teaching and three separate screen teaching.

All-channel Annotation

Enable to annotate under Android system and

Windows system.

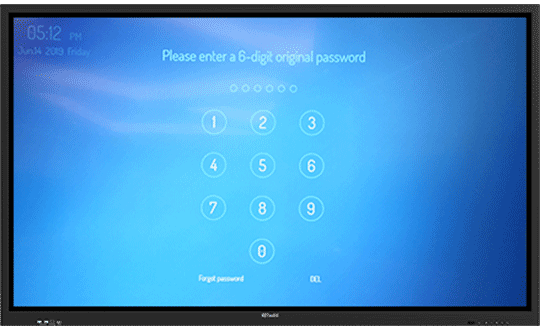

Power On/Off Lock and Screen Lock can

be Set with A Password Respectively

Support to lock screen and lock power on/off button

to avoid student

malfunction and secure privacy.

To compare with our other IQTouch Series

RESOURCE FOR YOU

Resource for you

Product Tag

Send us a message

Get in touch

-

![icon-phone]() +86-591-38202660

+86-591-38202660

-

![icon-mob]() +86-15280405902

+86-15280405902

-

![icon-mail]() iqboard@iqboard.net

iqboard@iqboard.net

-

![icon-addr]() 6th Bldg. High-Tech Base.

6th Bldg. High-Tech Base.

Fuzhou FuJian Prov. China

Solutions

Copyright © 2017.Returnstar Interactive Technology Group Co., Ltd All rights reserved.